Relying on Docker to Update Industrial Asset Management Systems Faster

On-premises asset performance management

Asset Performance Management (APM) plays a vital role in the world of Industrial Internet of Things (IIoT). APM builds on the concept of digital twins and adds advanced analytics to view the health of assets (machine and equipment) in real time—minimizing unplanned downtimes, monitoring changing risk conditions, and optimizing workflows.

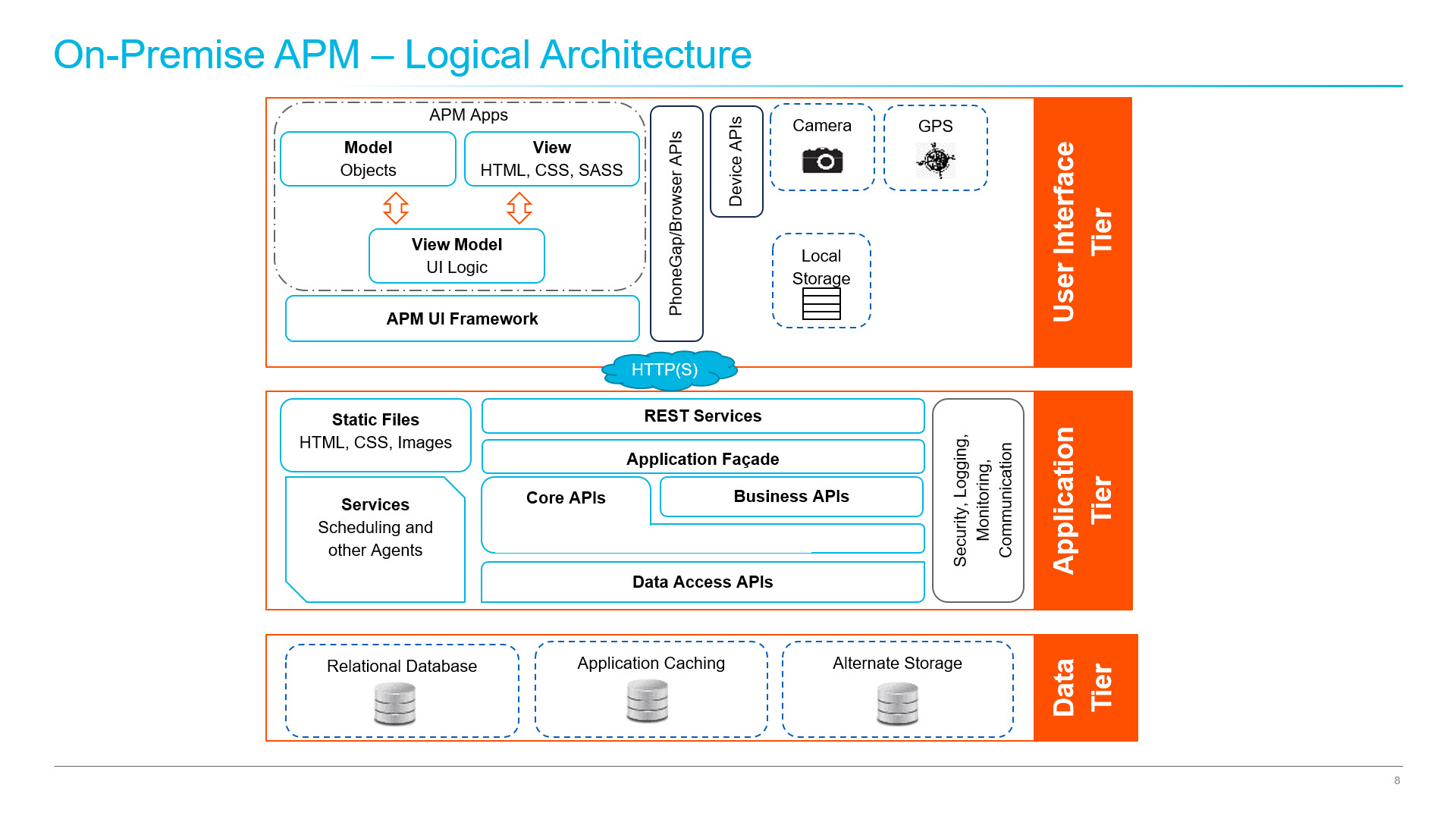

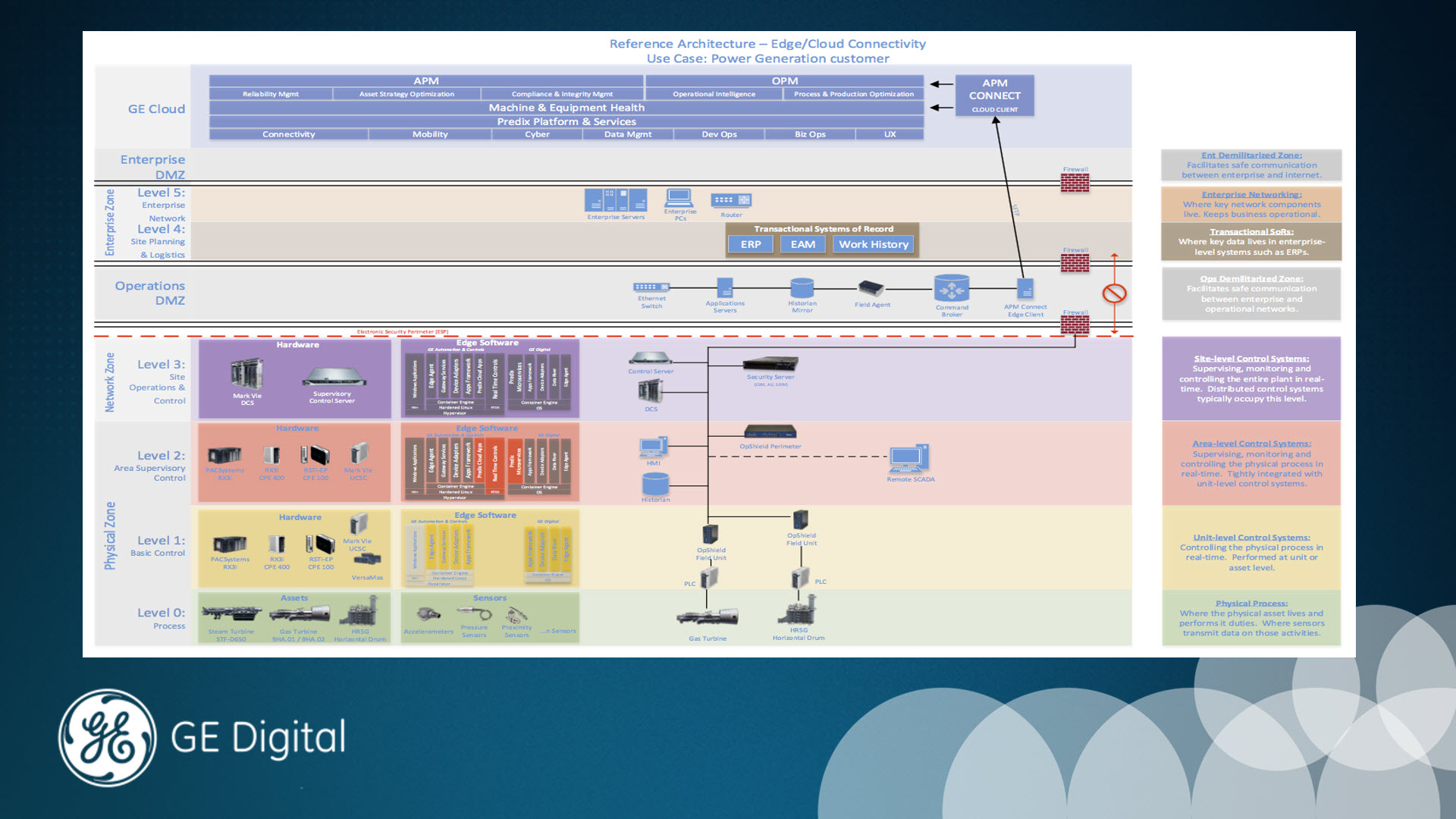

A simplified architecture of the on-premises APM

A simplified architecture of the on-premises APMHowever, very few organizations are willing to have their data stored on the cloud. “We recognized that there’s a big play for APM on-premises,” says Peter Ngai of GE Digital. “Somehow, we have to marry both.”

“About 90% of customers don’t really want to place all their data into the cloud. They don’t have that trust aspect that everything on the cloud will run on real-time like everything on-premises.”

—Peter Ngai, GE Digital

At a recent Predix meetup, Peter revealed the problems associated with moving software to the edge:

- Unlike software that’s deployed on the cloud, it’s a lot more difficult to maintain and update software that’s on the edge.

- Update cycles took too much time.

“What we usually do is we’d have a mirrored system at the edge and we upgrade that to the latest patch and test it thoroughly,” Peter said. “It might take up to three months before it gets rolled onto production.”

Previously, GE relied on two methods for rolling out new updates:

- sending professionals to the location and have them perform the upgrades

- sending links to the client containing the upgrades

Both of these solutions were slow and unreliable. “(Client) systems are running 24/7 and they don’t want them to stop,” explained Peter. So, another approach was needed; the issue was aggravated by Windows use at many customer locations.

Where is the edge?

To understand edge computing or fog computing, we first have to know where the edge is.

A reference architecture of a GE plant from the floor level to the cloud

A reference architecture of a GE plant from the floor level to the cloudAccording to Peter, the Operations DMZ—where the Field Agents are installed—is where all the edge technology is deployed. As he put it, the Operations DMZ has access to both the IT and the OT zones, and poses a place, where the edge technology will be.

In computer security, demilitarized zone, or simply put DMZ, represents a physical/logical subnetwork, containing and exposing an organization’s external-facing services to an untrusted network, usually a larger network, such as the Internet. So, what Peter means by the Operations DMZ can be basically called the Field Agent layer.

Field Agents are small devices that provide secure connectivity to the Predix cloud. They have two primary functions:

- collecting and sending data to and from the cloud

- serving as a computing platform for edge software, such as APM

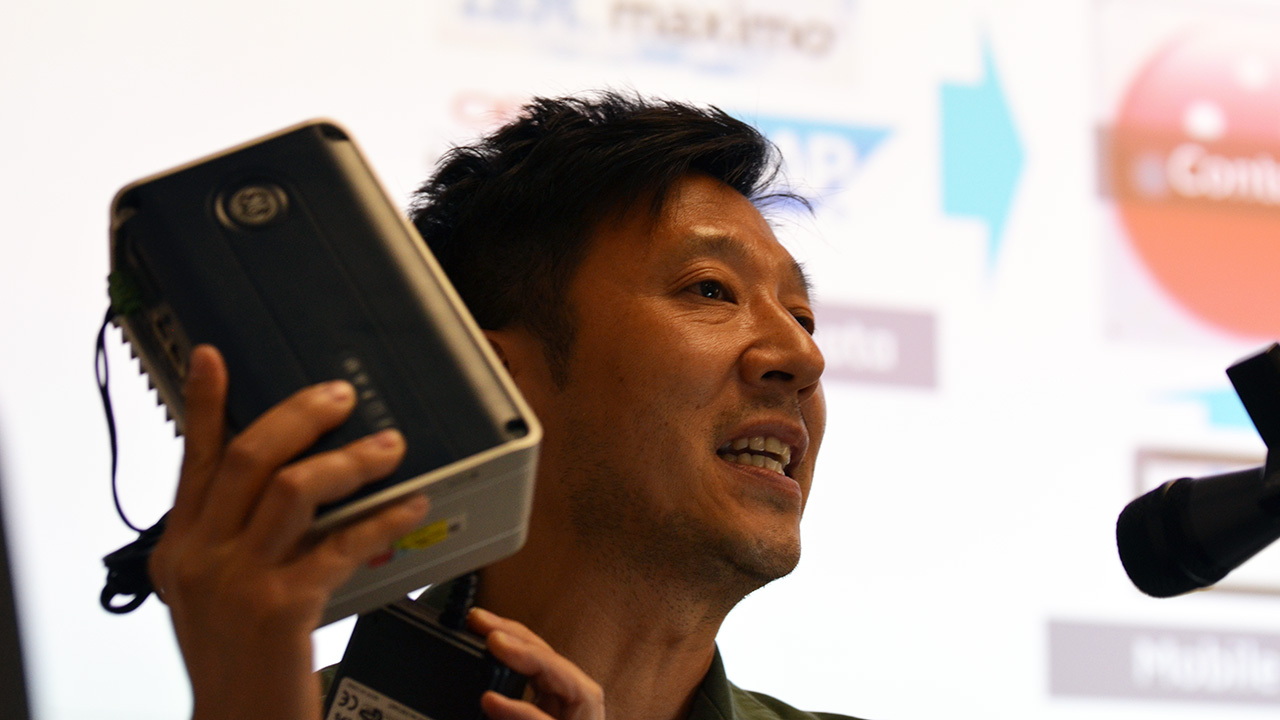

Peter Ngai holding a Field Agent

Peter Ngai holding a Field Agent“We consider the Operations DMZ part of the edge, and it’s very hard to upgrade software there. We can’t keep sending links to customers, saying upgrade when you can.” —Peter Ngai, GE Digital

Containerizing deployments

There had to be an easier method for managing edge deployments and GE’s search led to Docker for Windows and containerization.

“We have to containerize software. We have to take an approach to make it easy to deploy.”

—Peter Ngai, GE Digital

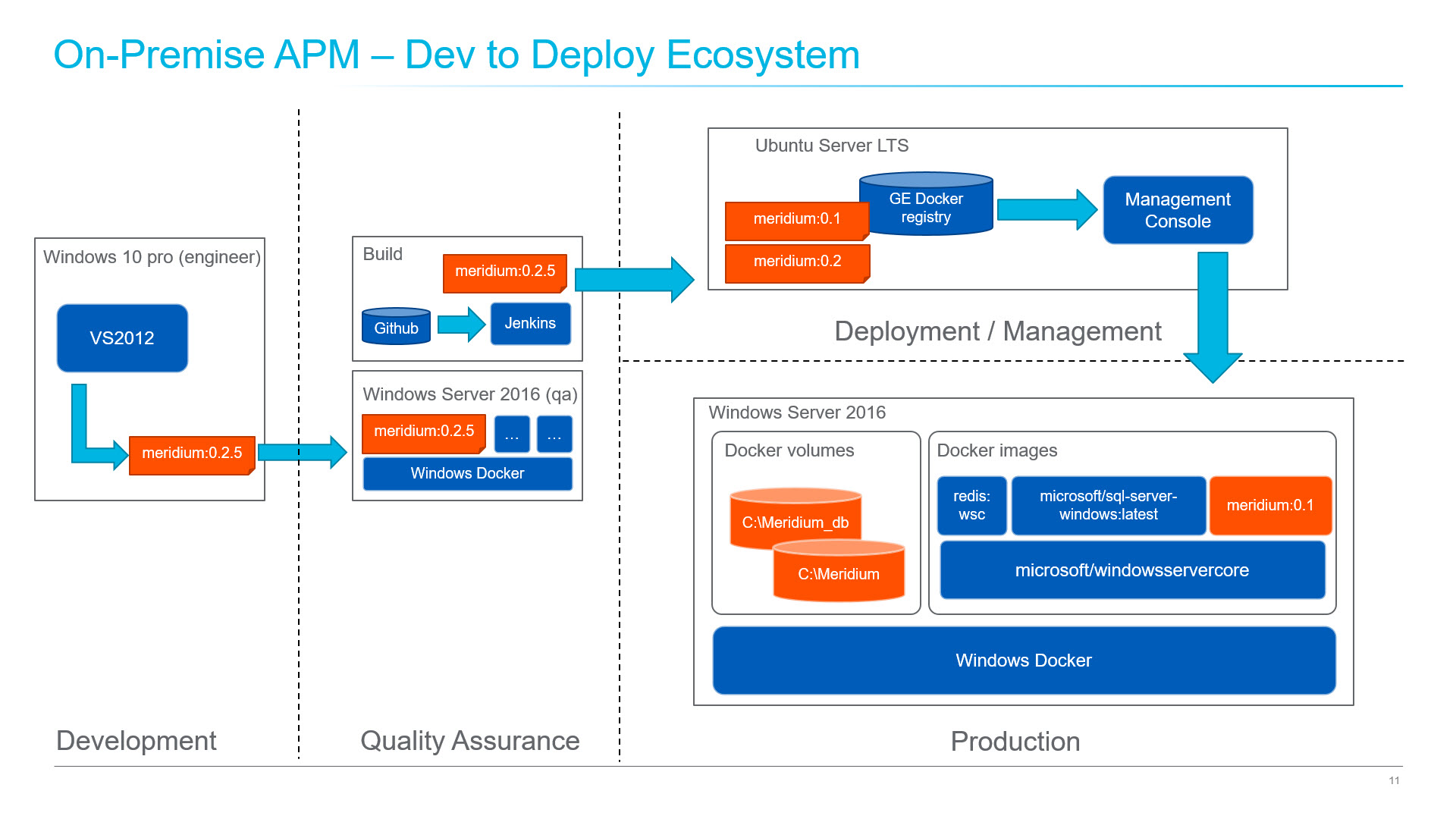

By referencing the ecosystem below, we can break down how containerization affects the deployment cycle.

- Developers create a Docker image of the update.

- Quality assurance engineers can test the image without having to worry about dependencies.

- Once tested, the Docker image is passed to the deployment management system.

- The deployment management system can then roll out the Docker image to production for updates.

Containers used in development to deployment

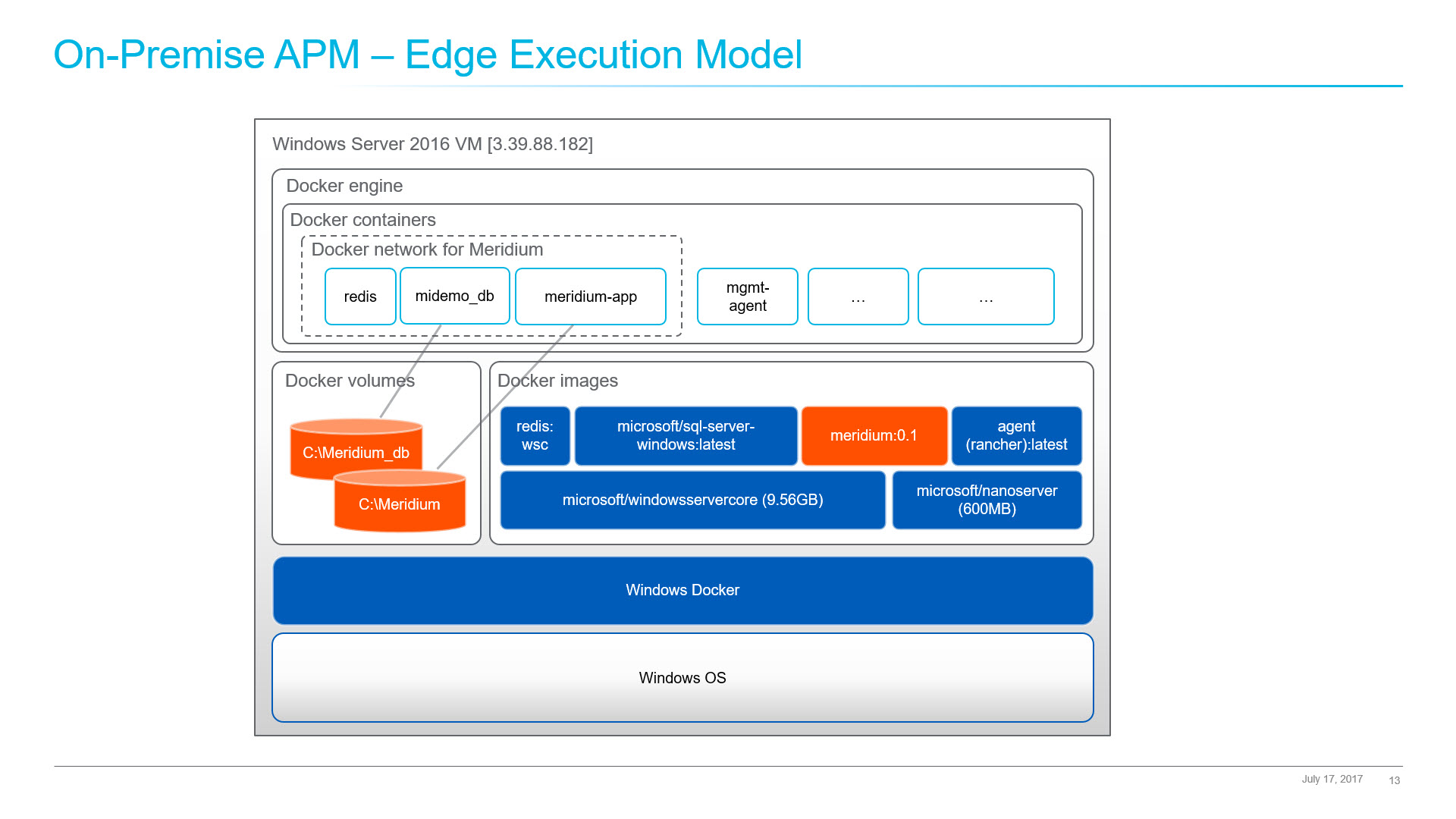

Containers used in development to deploymentThe edge execution model below illustrates how the customer data is separated as Docker volumes. With this model, updating the system requires minimal to no downtime using blue-green deployment.

The edge architecture with containers

The edge architecture with containersThe shift to containerization also provided additional benefits:

- By using Docker, development teams are able to easily expand the system with off-the-shelf Docker images.

- The system is much easier to maintain due to customer data being externalized from Docker images into Docker volumes.

“You can run something on Docker, and it will hold it down. Everything is containerized, so you don’t have to worry about dependencies.” —Peter Ngai, GE Digital

Industrial use of Windows

With the manufacturing industry embracing Industrial IoT, more and more organizations may look to edge computing to keep critical data on-premises. With containerization, these organizations can also keep their systems secure and up-to-date.

One of the unexpected takeaways from the meetup was the fact that most manufacturing companies use Windows instead of Linux. Peter attributes this to a case of who was the first all those years ago and who had the better looking user interface. Could this oversimplified reasoning also apply to the containerization of software at the edge years ahead?

Want details? Watch the video!

Table of contents

|

Further reading

- Real-Time Monitoring for Industrial IoT: Engaging Operational Technology

- Optimizing Industrial Internet of Things with Objects’ Digital Twins

Related slides

About the expert