Real-Time Monitoring for Industrial IoT: Engaging Operational Technology

The lack of real-time monitoring in IIoT

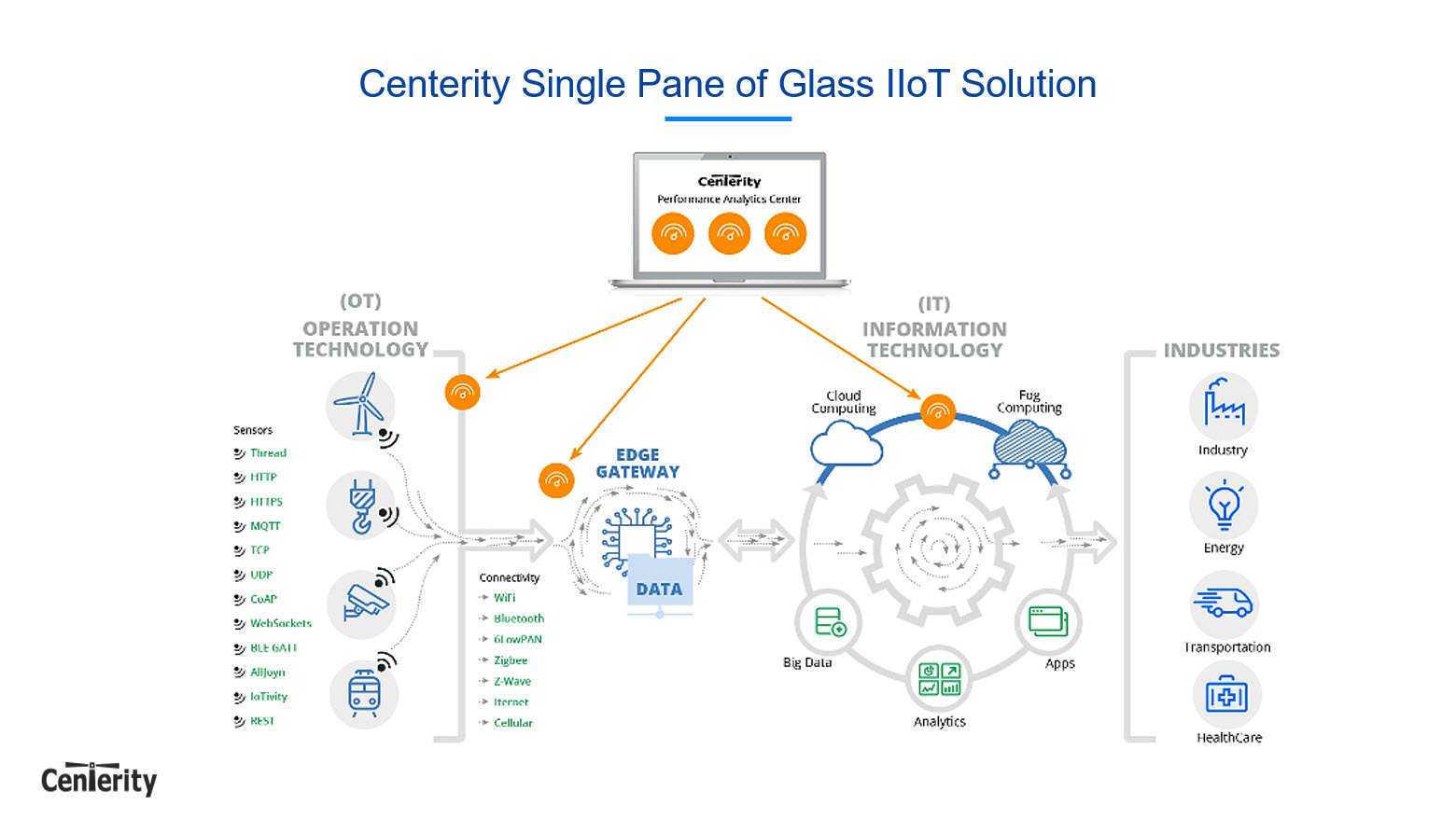

Operational Technology (OT) comprises the hardware and software systems that monitor and control physical equipment. It includes devices, sensors, and software that identify and detect a change in physical devices, processes, and events within an enterprise IT infrastructure.

Correlating data from Operational Technology and IT, then organizing it into a “single pane of glass” was the topic of a recent webinar by John Speck of Centerity Systems.

“With the rapid growth of connected devices and their data, the looming challenge is not just how to connect those devices to one another and manage them, but how to connect them meaningfully and reliably to the traditional IT and business processes they power.”

—John Speck

Most enterprises have no single solution available to monitor every technology in the environment, John noted, and there are “too many technology-specific tools needed, and no real-time correlation of performance data.”

In this case, there is no way of providing a “single pane of glass to the entire ecosystem,” he said.

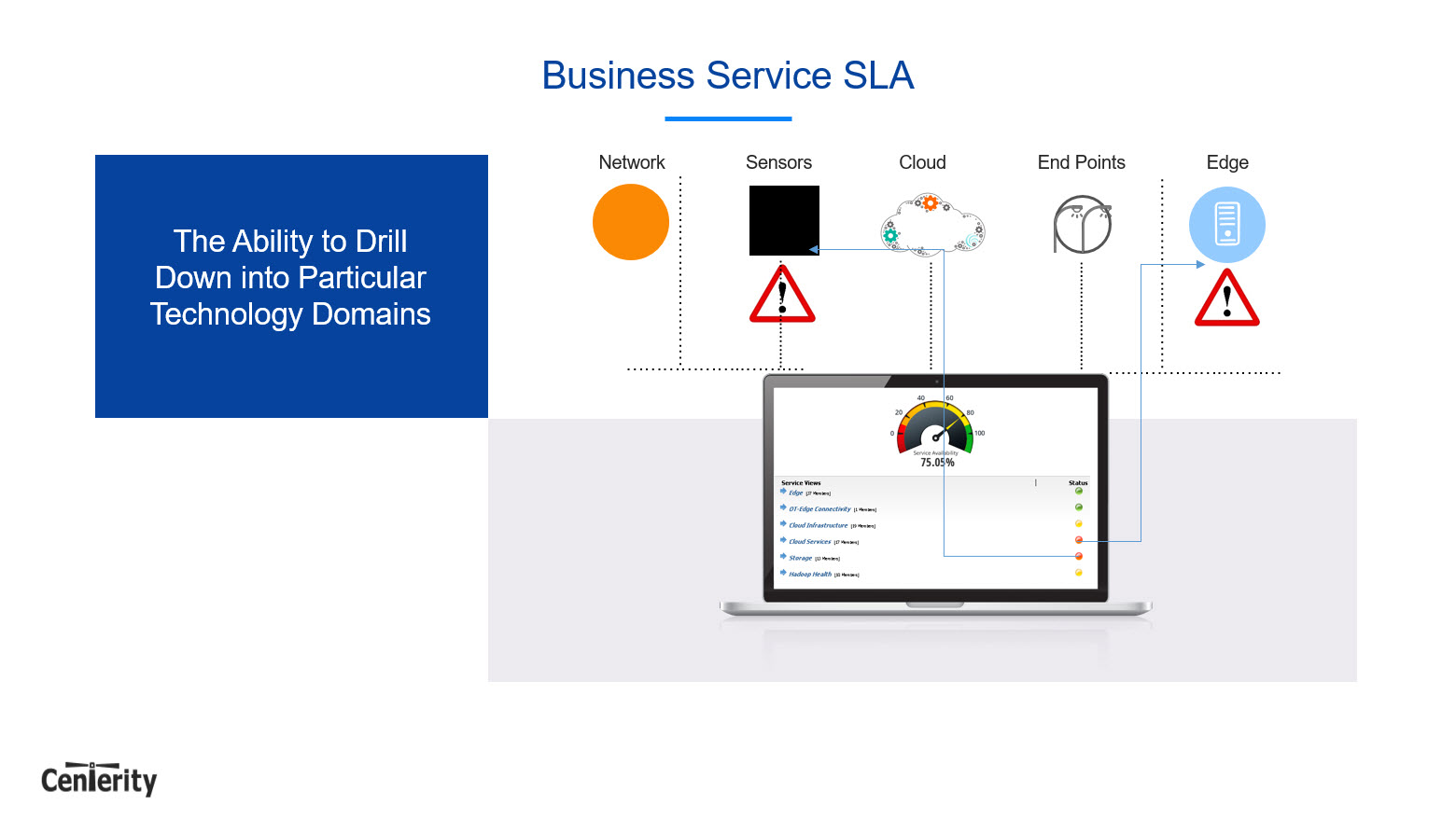

“Without a complete view of the entire system, you can’t see which individual component is causing service degradation. It takes a long time to find and resolve issues. What’s required is real-time monitoring of the edge.” —John Speck, Centerity Systems

Through the single pane of glass

John outlined some key factors to keep in mind while addressing the problem of correlating OT data to develop a solution that provides the real-time monitoring:

- What performance benchmarks to consider when incorporating OT into your existing IT practice?

- How to create consolidated process views of your overall OT/IT landscape for ease of operations and proactive issue resolution?

- How implementing a business-oriented OT/IT strategy can help you attribute measurable ROI to technology initiatives?

- How sharing process views with executives, staff, and customers promotes common goals and creates a cycle of continuous strategic improvement?

“If we take a step back from connected devices and sensors, we normally focus on and broaden our view to see everything else that allows us to capture data and drive business,” he said. “This includes the network and compute infrastructure, cloud platform, databases, etc.”

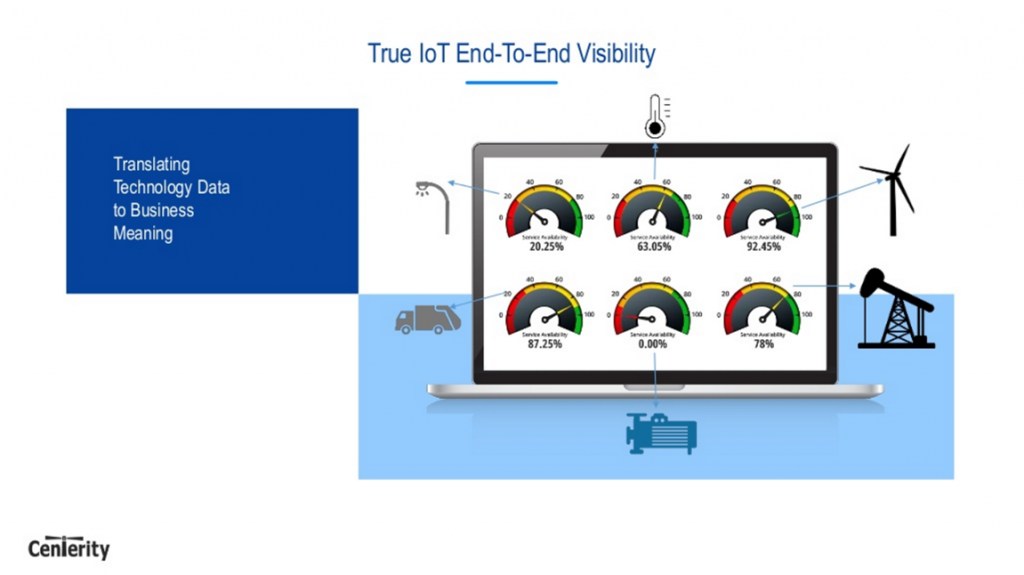

“What’s crucial is translating technology data into business meaning,” he continued. “You have to look at the environment holistically, so you can see every potential point of failure and see the impact of one aspect on another. Once you’ve aligned all the devices within an IIoT infrastructure and the applications on either the edge, cloud, or on-prem, then you can represent all of it as a business service instead of just seeing silos of data.”

Challenges and requirements

John noted that “IIoT environments are necessarily complex,” listing several factors:

- Multiple communication methods complicate connectivity and interoperability.

- Diverse data models increase ecosystem management complexity.

- Service use case and ecosystem definitions change after deployment.

- Custom-made sensors and actuators are expensive. On the other hand, COTS (off-the-shelf) devices are affordable but are not tailored for ecosystem’s security, service model, and communication requirements.

There are also critical requirements to meet:

- Dynamic ecosystem scalability and maintenance

- Adjusting COTS devices to the ecosystem’s security and communication requirements with no firmware changes

- Secure device intercommunication across the entire ecosystem

- Potential need to switch out devices and change protocol methods over time, resulting in a constant flux of data types and flows

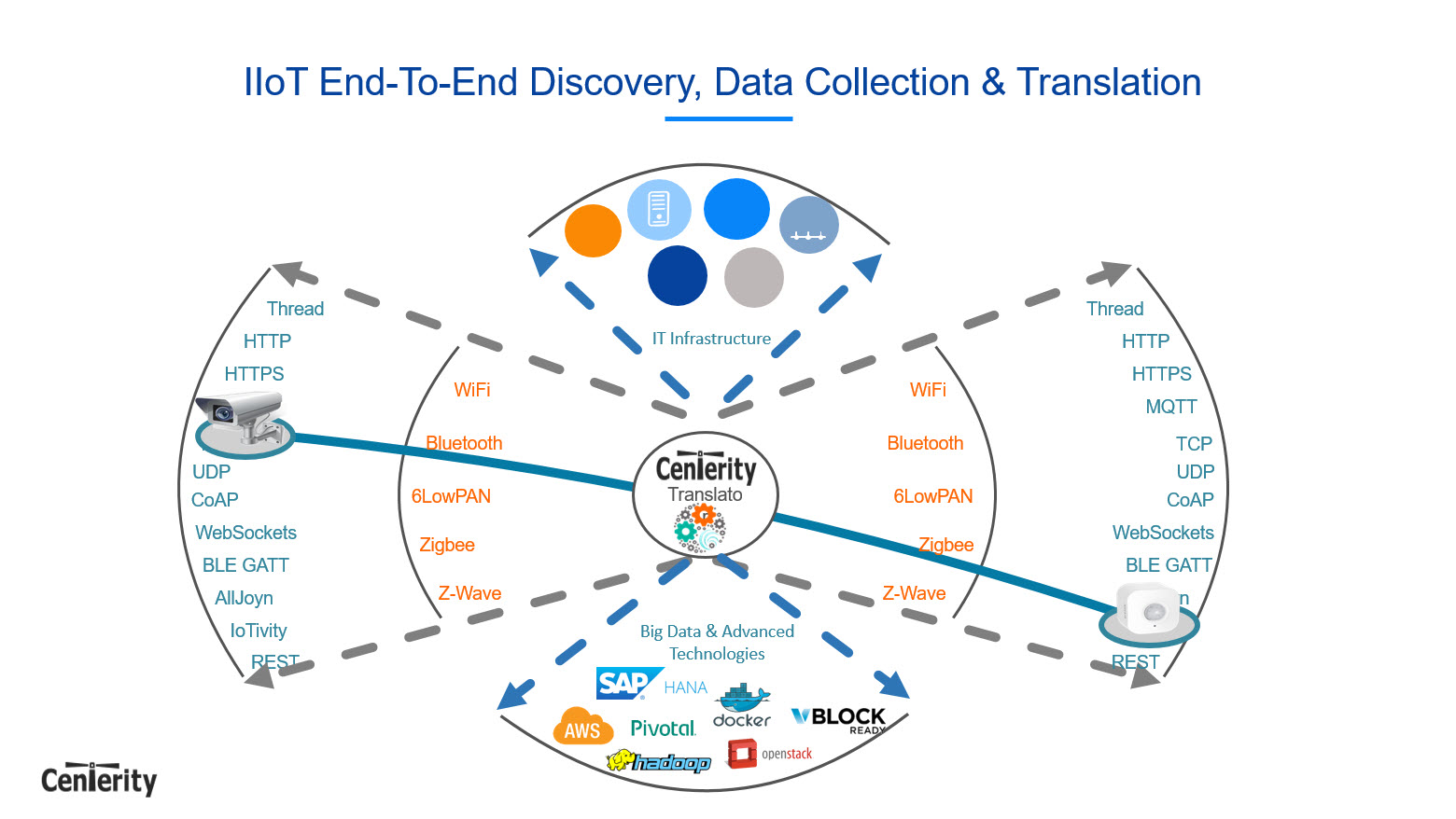

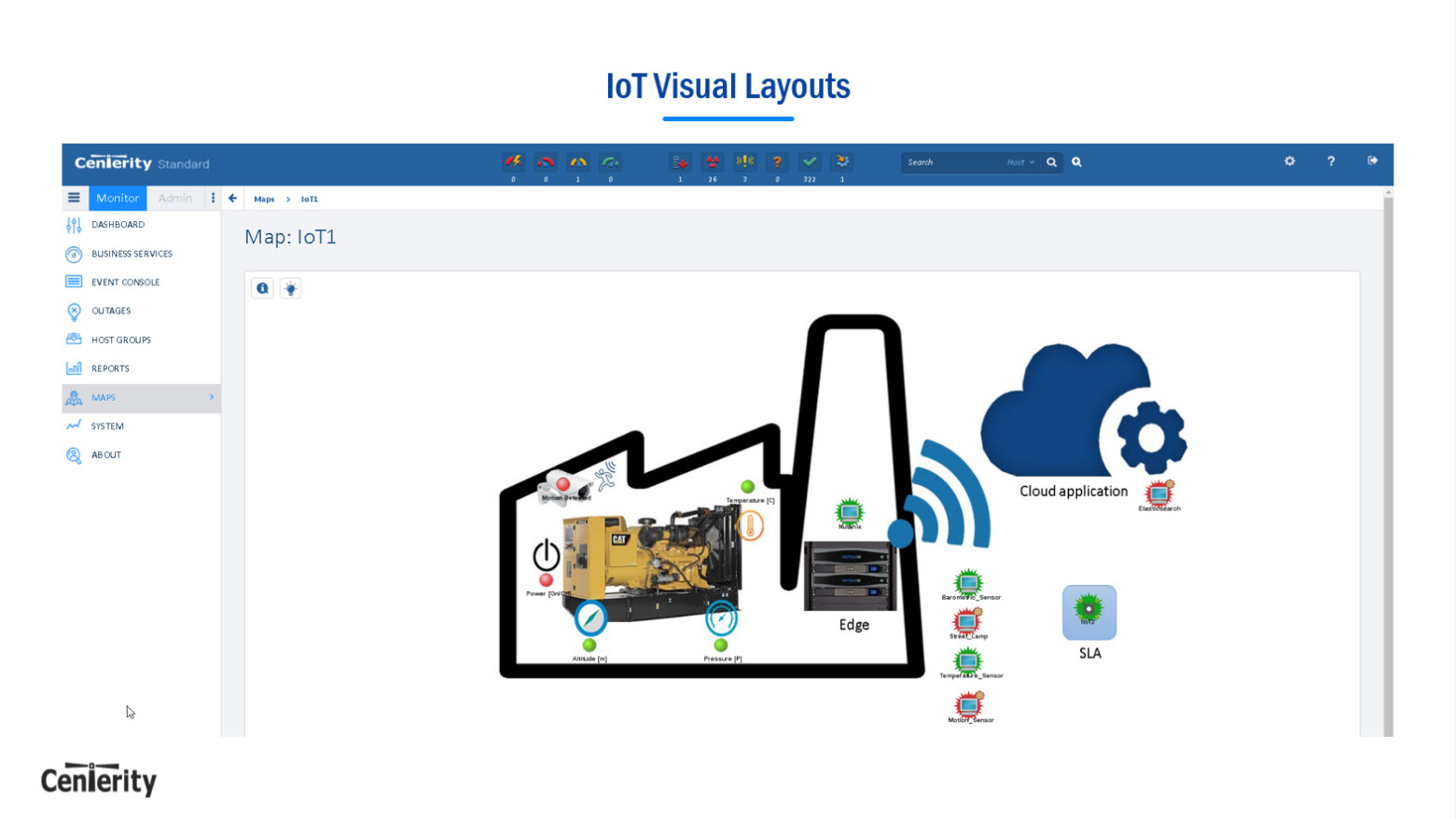

In the end, “there will be a requirement for wide connectivity support for almost any communication method, protocol, and IT technology,” John noted. “So, you need a single abstract service model that translates IoT device data models at runtime into business and operational service views.” A view of end-to-end discovery to develop such a model looks like this:

Another key aspect is “a connected abstraction layer that manages disparate devices through an API translator,” he said. “Then you can combine your common abstract language with all the devices’s specific languages and low-level code.” The result is a look at performance data that is presented according to business processes.

Taking a multi-tenant approach

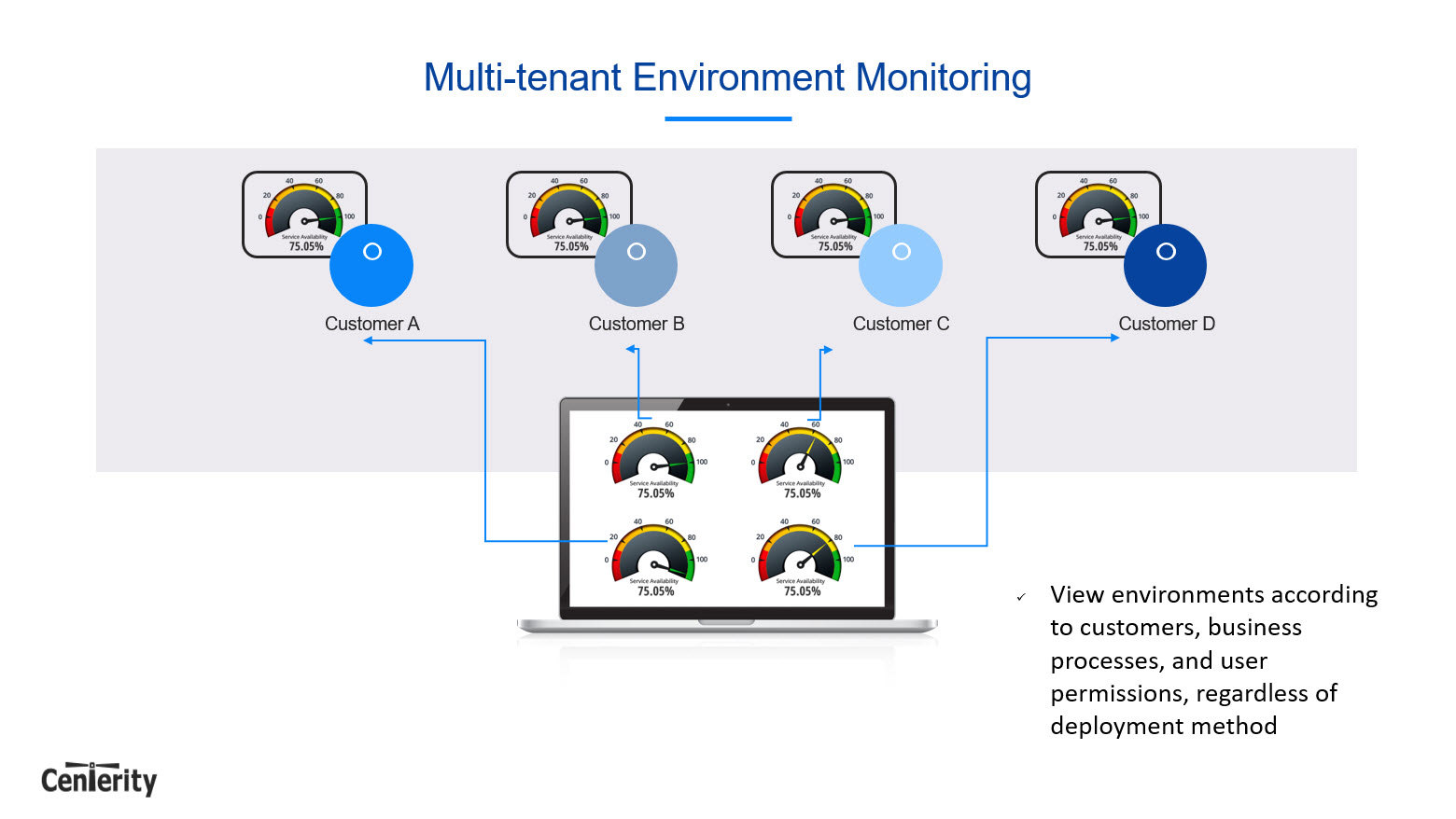

Centerity believes in a “multi-tenancy approach, so customers and environments are segmented according to user permissions, and users therefore only see environments that are most relevant to them,” John said.

“With this approach,” he said, “you can scan, discover, and add any devices and apps on the network, then visualize the environment from end to end, correlate performance data from every technology layer, and integrate the platform with any associated service to feed data to it. This could be a service desk, an ERP system, or whatever is using that data. Then, you can organize the environment to analyze it through the single pane of glass, according to whatever is most critical to running your business.”

So, according to John, bridging Operational Technology and IT allows for improving business/process health with minimal unplanned downtime. As a result, mean-time-to-repair decreases while improving efficiency and troubleshooting process and enabling a proactive approach of an IIoT deployment.

Want details? Watch the webinar recording!

Related slides

Related links

- Optimizing Industrial Internet of Things with Objects’ Digital Twins

- Adopting an IoT Platform: Things to Know and Pitfalls to Avoid

- Mobile Devices Are Propelling Industrial IoT Scenarios

- Applying Data-Centric Approach to Unify IoT Security Policies

About the expert