The Impact of IoT on the Economy and Business Models

What does IoT mean for the economy?

This question was the focus of a talk held at a Predix and IoT meetup in Boston. The presentation was lead by Robert B. Cohen of the Economic Strategy Institute.

As it turns out, it means a lot. Robert did however put emphasis on two main points. IoT introduces many unappreciated efficiencies such as cost cutting and innovations to production. IoT also provides an enhanced competitiveness to firms adopting the technology either through joint products or providing zero defect or zero downtime guarantees. However, some changes to business models will be required—alongside with new employee skills.

“With predictive analytics, companies will be able to save as much as $400M a year.” —Robert B. Cohen, Economic Strategy Institute

Robert went on to explain how IoT could change the landscape of the electrical, mechanical, and service industries. He listed some of the effects it could achieve:

- Provide greater control over production

- Reduced costs

- Expanding production is easier, raising revenues

- Facilitate linking manufactured products to services

- Monitors engines in real-time, reducing unexpected maintenance

- Extends lifetime of products

- Supports zero defect or zero downtime guarantees

- Speed up production or service development

- Actively identifies issues in products while they are produced

- Reduces errors and poorly produced products, eliminating time lost

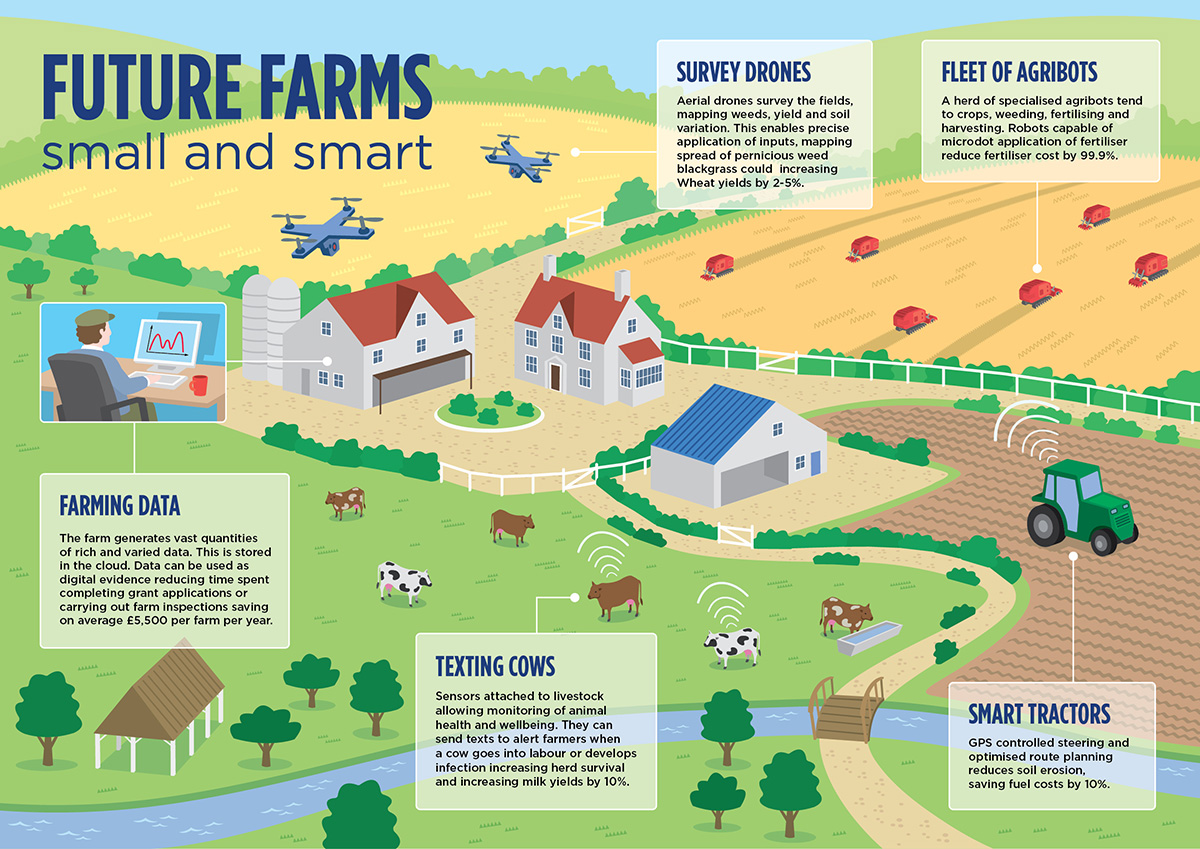

For added effect, he quoted Ohio State’s Dr. John Fulton who said, “If you’re going to do farming in the future, this is what you are going to use—precision agriculture which is moving digital data. This includes precision agriculture, prescriptive agriculture, and big data.”

Photo credit: Nesta

Photo credit: Nesta“Precision agriculture can probably increase the efficiency of U.S. farming by over $1B a year. That’s a 10–15% increase in farming revenue.” —Robert B. Cohen, Economic Strategy Institute

Improvements to production and efficiencies

Robert moved on to specific changes IoT had on production.

- Improve efficiencies with analytics and robots on the factory floor

- Just in time materials

- Timing progress on the line

- Expanding production by using a moving assembly line

- Cost savings plus expanding the scale of production

- Precision Agriculture

- Combines GPS, big data analytics, and wireless communications

- Optimizes fertilizing, watering, and harvesting

- Wireless links between vehicles reduces process time

“Using wireless communications, harvesters can run through a field without a farmer sitting inside them so they can harvest 24 hours a day.” —Robert B. Cohen, Economic Strategy Institute

He then proceeded to talk about new efficiencies.

- Big data reduces downtime for Rolls-Royce’s engines

- On-board analytics transmit only data that deviates from the normal, allowing Rolls-Royce to address problems before they arise,

- By monitoring performance in great detail, Rolls-Royce can offer contracts for service,

- Milestone Merck Insomnia study (2004)

- Electronic reporting smaller deviation compared to if patients used paper to report clinical results

- Sample size needed for reliable clinical trial could be reduced

- Phase 3 clinical trial savings of $1.5M

- Avoided “parking lot syndrome” or taking too much time to fill in results on paper forms

As an example, he pointed out Rolls-Royce which offers Power by the Hour, a service made possible by having sensors attached to engines that transmit data deviating from the norm.

Changes to business models

According to Robert, IoT will not only affect a company’s competitiveness, it will also affect the individual employees. IoT means the inclusion of predictive analytics, real-time analytics, and big data just to name a few.

“We will see IoT changing what determines how well a company can compete.”

—Robert B. Cohen, Economic Strategy Institute

With IoT on the rise, companies will be expecting and training their employees to cover skills that weren’t much in demand before.

- Analytical skills

- Analytics employees will need baseline computer skill as well as familiarity with data processing frameworks like Hadoop.

- Software development

- Boeing is requiring programmers to work on simulations and analytics.

- Rapid development of new services in cloud ecosystems; testing and development of new software for applications

- Infrastructure management

- Big data lakes require familiarity with virtualized environments.

There will also be changes to business models as more and more companies adopt the trend.

- As-a-Service to mechanical or electronic products

- Rolls-Royce. Power by the Hour

- Michelin. Kilometer by the Hour

- Guarantees of high-level performance

- Rolls-Royce. Zero-based Disruption

- FANUC. Zero Downtime

“Companies such as Rolls-Royce and Michelin, as a result of selling the service, control all the aftermarket.” —Robert B. Cohen, Economic Strategy Institute

What the future holds

There’s a lot of things we can expect once more and more companies get involved with IoT. Being able to capture continuously streamed data and analyze it rapidly will make it easier to respond to what would usually be considered as complex events. Continuous service deliveries for software written on cloud computing infrastructure will allow developers to address a malfunction before it causes a disruption. In a word, it’s all about efficiency.

To end, Robert cited Cycle Computing processing decades worth of genome analysis in a few hours. He concluded, “that kind of efficiency is going to drive real change. If we saw a lot of processes that are that long in the economy being chopped down to a fraction of what they usually are, we’re going to see a lot of efficiencies and get things done.”

Want details? Watch the video!

Table of contents

|

These are the slides presented at the meetup.

Further reading

- Bringing Healthcare Home with the IoT

- IoT for Airlines: Smart Baggage Tracking with RFID Tags and Cloud Foundry

- A Challenging Path to Building Predictive Analytics into IIoT Deployments

- IoT in Healthcare: “The Internet of Caring Things”

About the expert